The Sky is the Limit with RIM Molding

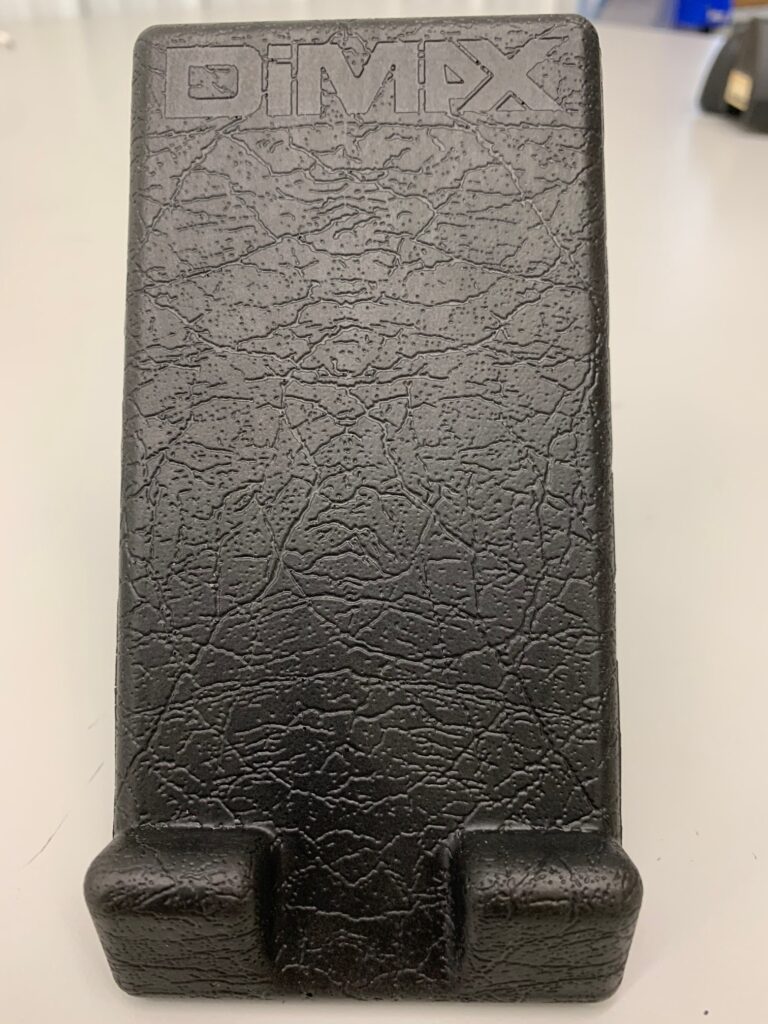

DiMax handles manufacturing needs for non-metallic materials, specifically any applications that require a tough urethane skin with memory foam that absorbs shock, vibration, and compression. RIM foam molding is suitable for many applications and we have quick lead times!

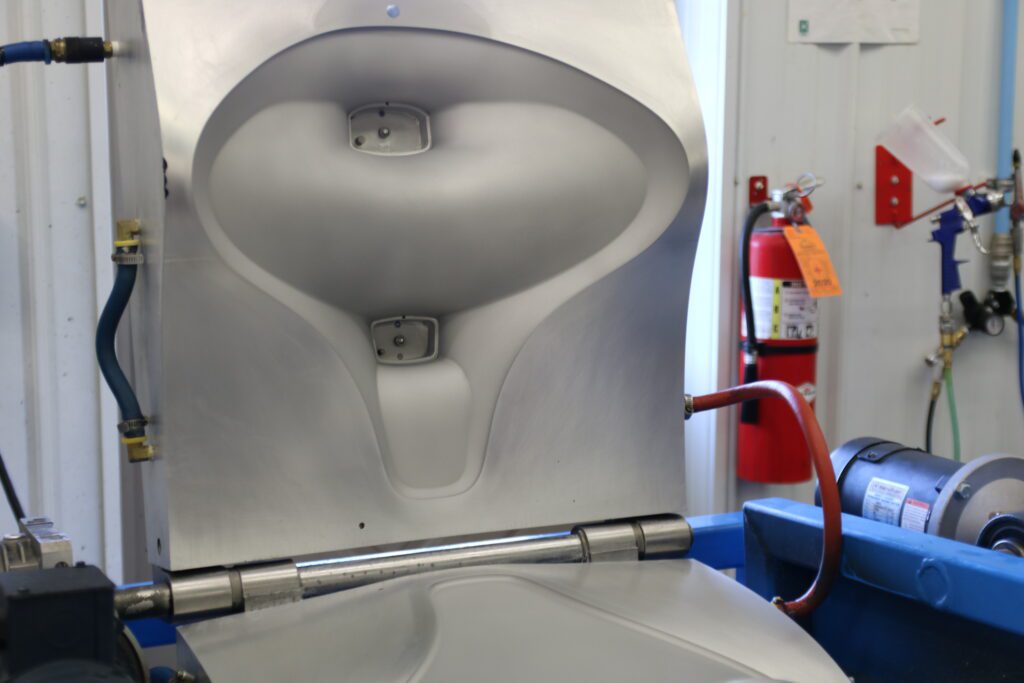

Need a Larger Part?

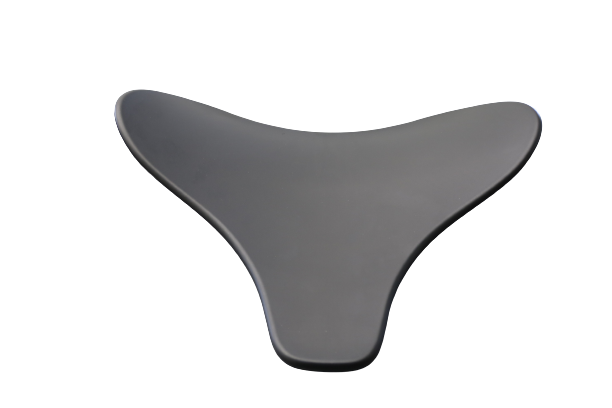

Our reaction injection molding process allows us to produce various shapes, sizes, and densities that are incredibly durable, tear-resistant, and easy to clean.

RIM Foam Part Examples

Take a closer look at RIM molded parts that play an important role in everyday products they’re used to create, then contact us to collaborate, offer ideas to fit your design, and make your entire project successful!

Get your RIM foam molded project started today by requesting a prototype or quote.